A356 Aluminum Casting is a fascinating and versatile process that has been utilized for centuries to create intricate and durable metal objects. From engine components in the automotive industry to decorative sculptures, aluminum casting plays a vital role in various fields. In this comprehensive guide, we will delve into the art of aluminum casting, exploring its history, the casting process, techniques, and its contemporary applications.

A Brief History of Aluminum Casting

Aluminum, one of the most abundant metals on Earth’s crust, has a rich history in casting. Despite its abundance, aluminum wasn’t readily available for casting until the 19th century. In 1825, Danish physicist Hans Christian Oersted successfully isolated aluminum, marking the first step towards its widespread use.

The breakthrough for aluminum casting came in 1886 when Charles Martin Hall and Paul Héroult independently discovered the electrolytic process to extract aluminum from bauxite ore. This discovery led to a significant drop in the cost of aluminum production, making it accessible for casting purposes.

The Aluminum Casting Process

Aluminum casting involves transforming molten aluminum into a desired shape by pouring it into a mold. This process can be categorized into two main methods: die casting and sand casting.

1. Die Casting

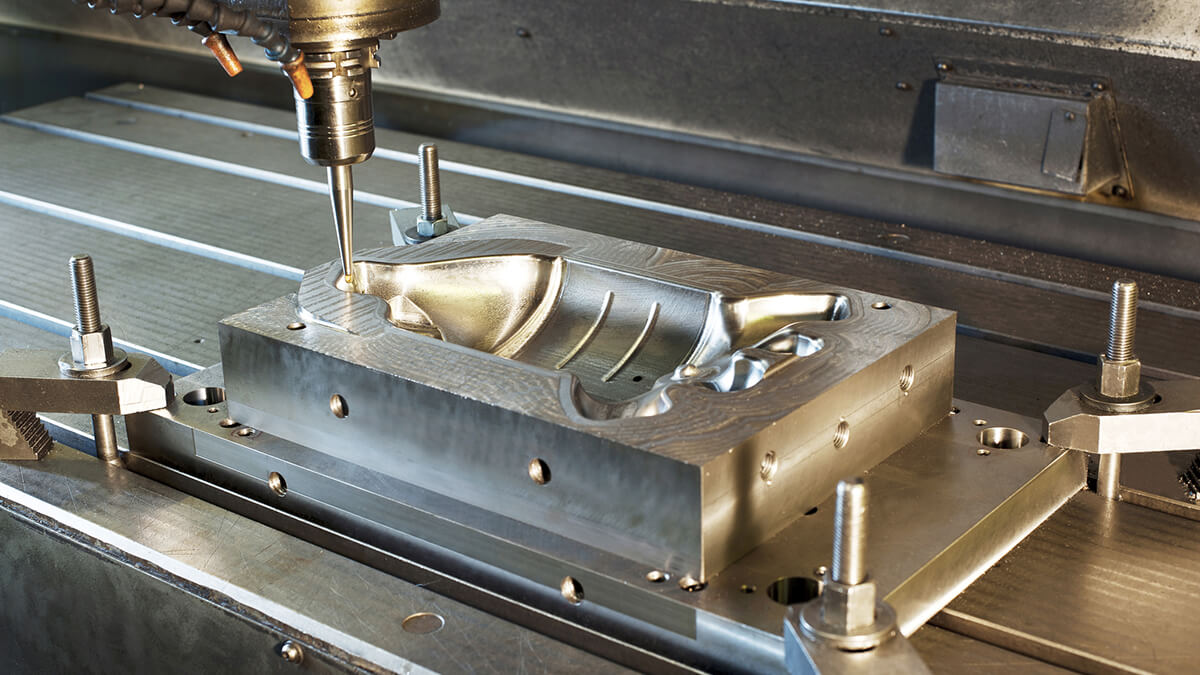

Die casting is a precision-based method used to create intricate and consistent aluminum parts. It involves injecting molten aluminum into a die, which is a mold made of hardened steel. The high pressure ensures that the aluminum fills the mold precisely. Die casting is commonly used in the production of automotive parts, consumer electronics, and more.

2. Sand Casting

Sand casting, on the other hand, is a more traditional and versatile method. It involves creating a mold using sand mixed with a binder. The mold is then shaped according to the desired object. Molten aluminum is poured into the mold, and once it cools and solidifies, the mold is broken to reveal the casting. This method is commonly employed for artistic and custom-made pieces.

Techniques in Aluminum Casting

1. Green Sand Casting

Green sand casting is one of the most common techniques in sand casting. It involves using damp sand mixed with clay as the mold material. The moisture helps the sand hold its shape and aids in the casting process. Green sand casting is used for a wide range of applications, including engine blocks and artistic sculptures.

2. Investment Casting

Investment casting, also known as lost-wax casting, is a precision casting method. It involves creating a wax pattern of the desired object, surrounding it with a ceramic shell, and then melting out the wax to create a mold cavity. Molten aluminum is poured into the mold, and the ceramic shell is removed after the casting cools. This technique is ideal for creating complex and intricate parts with high detail.

Contemporary Applications

The art of aluminum casting has evolved significantly over the years, leading to its use in diverse applications:

1. Automotive Industry

Aluminum casting is widely used in the automotive industry for components such as engine blocks, cylinder heads, and transmission cases. Its lightweight yet durable properties make it an excellent choice for improving fuel efficiency.

2. Aerospace

Aerospace engineers use aluminum casting for aircraft components like landing gear, structural parts, and engine components due to its strength-to-weight ratio.

3. Art and Sculpture

Artists and sculptors continue to explore aluminum casting for creating intricate and visually stunning sculptures. The versatility of the process allows for the production of both functional and decorative pieces.

4. Industrial Machinery

Aluminum castings are integral components in various industrial machinery, contributing to the efficiency and durability of equipment used in manufacturing and construction.

Conclusion

The art of aluminum casting is a blend of craftsmanship, science, and technology. Its rich history and modern applications showcase the adaptability and versatility of this casting method. Whether it’s for producing essential parts in the automotive industry or crafting intricate sculptures, aluminum casting continues to shape our world in remarkable ways. As technology advances, we can expect even more innovative applications for this ancient art form.